The Apparel Career That Began with a Twenty Five in a Million Chance

As a child, Alka Chopra thought she would grow up to be a doctor. But she always took a keen interest in apparel, designing and making her own clothing since she was twelve years old. After earning her Bachelor’s in Economics at Delhi University, she applied to fashion school. Out of one million applicants, Chopra was accepted for one of only 25 seats at the newly opened National Institute of Fashion Technology (NIFT) in Delhi, where she studied Technical Design.

Her career in apparel followed, bringing her to New York City for the first time. Years later, she’s now Senior Director of Technical Design for PVH Corp, whose brand portfolio includes Calvin Klein, TOMMY HILFIGER, Van Heusen, IZOD, and more. Below, she talks about her path to the top.

How did you start your career after fashion school?

My first job was with a company called Associated Merchandising Corporation which was later acquired by Target Corporation. My competitor at the interview was a seasoned pattern maker and I had little hope of being chosen. I was excited when I got the job and even more that I would go to the USA for training for a month. Traveling first class as a 24-year old on my own merit was unheard of at the time.

This was the first time anyone from my family was going to NYC. I was cautioned not to take 42nd Street, as it was not safe. Well, how do you do that if your hotel is on 50th and office on 40th Street? I walked daily back and forth daily from hotel and office. I got to know the city and fell in love with it.

After training, I was the first person to set up the Technical Design department in India in apparel. I was responsible for all approvals. At the time Technical Design was a male-dominated field in India. I worked hard. I was persistent and partnered with the male pattern makers to eventually earn their respect.

Could you share with us a few things you did to “gain respect from the men you worked with?”

Give respect and get respect back always works. I knew they had several years of practical experience and could learn from them. I approached them by asking for what advice they could give me? I understood how they worked and asked what was the most challenging aspect of their job. One example- I recall was that it was difficult for them to understand fit reports (they were not fluent in English). I offered that we work together wherein I would be happy to help them translate. They taught me the differences between production and sample pattern. I would suggest alternate ways of correcting pattern but always gave them respect by asking them if it would work as I was still learning from them. Slowly they realized that the suggestions I made resulted in the right-first-time approval.

After working in India for a few years I moved to NYC. I started as a measurer and rose to be a Senior Director over the years. This was not easy, as I had to prove myself. I wanted a different experience, so I moved to Dubai where again I set up a Technical Design department.

The biggest loves in my job are leading and coaching, strategy, digital transformation, data analytics, change management, process improvement, and simplification. It’s all about the right work, the right place, the right people. The biggest challenges are working with teams and people who resist change and have a negative outlook.

What are your goals for the future?

To set your goals, one should know what your vision, mission and valuers are. I want to continue with Digital transformation and to eventually conduct all approvals digitally. Learn from other industries and adapt to Apparel. Grow to be a VP. and above. But above all, my true passion lies in making a difference in:

1- Taking fashion-forward for good

2- Continue to expand the culture of Inclusion and diversity

3- Stop animal cruelty

Could you explain a bit more about “digital transformation?”

Who would have thought a year ago that we could work efficiently and effectively from home 5 days a week. The world is changing so fast. Supply chains all over exponentially transformed through technology. Imagine how much faster technology will transform when we have a solution for combating COVID. These are exciting times and have forced all to think and work differently. Our industry is still in its infancy to adapt to digital tranformation. I envision there will be a time sooner than later wherein we will eliminate all physical samples. There will only be one pre-production sample prior to bulk production, just like aircrafts.

You shared with us that knowing your values is important- Can you share what your values are?

” It is important to know your own Values, Mission and Vision.” Alka

My Values: Compassion, dynamism, integrity, relationship, commitment and, courage

My Mission: To continuously grow (spiritually) by serving and fulfilling all my obligations and doing what I ought to do

My vision: To be the best servant leader

Looking to clarify or define your own values? I love this article from indeed.com; 6 Steps to Discover Your Core Values– check it out to come up with your own list which will help guide you in all your decision making.

You are a leader with a proven track record; what strategies do you use to create a healthy and successful team?

1. I work with my team on their learning plans as I believe in continuous growth. Periodically I ask them how I can better support them. There is nothing more rewarding than seeing your team grow. Investing in team growth isa win-win situation. 2- Coaching is often not as easy as one may think. Coaching is what I thrive for. For me, people and connections are very important. When team members pose problems it is easy to advise and/or problem-solve. However, I believe that to grown the team, I start by asking the team to identify the root cause of the problem and provide the best solution the team could think of. We then dialogue pros and cons. I ask questions as this provokes their thinking further. This way either they come up with more appropriate solutions or additional conviction of their original solution.

3- When working on specific projects I ask for volunteer. With this approach teams take ownership.

4- We allow each other the right to point out when we are not our most positive selves. We reset and move forward. 5- Being available to my team is critical. I have an open door (these days virtual door) policy. No matter how busy I am, I ensure to give them the time they need. 6- Having fun is key to building morale and a positive environment. We celebrate birthdays, work anniversaries, baby showers and bridal showers, and holidays. Yearly we participate in a team volunteer activity. 7- Provide exposure to senior leadership by encouraging and creating opportunities.

8- Small authentic gestures like- job well done, being verbal about being a great team, and passing the compliments that others make when the team is not present in the room goes a long way in building a positive environment.

9- Allowing room for errors gives the team the freedom to take risks. Creating a safe space for the team is crucial. Developing a culture of hindsight and learning vs blaming always works better.

10- My team knows that I always have their back. 11- I don’t manage them I lead them- they manage on their own as they know how best to do their job. I prioritize and create strategies

My advice, If you’re considering a career in this capacity, is to develop the following skills:

1. Leadership skills 2. High EQ 3. Cross-functional partnerships 4. Digital migration 5. Manufacturing & retail analytics 6. Vendor management 7. Product development 8. Conflict resolution

Some of your most striking accomplishments are the supply chains you’ve built in Africa and areas outside of China. How did you go about finding makers in these places that are less typically tapped for apparel manufacturing?

Africa was the highlight of my experience. Apparel is the second most polluting industry after petrol. The main reason is dye and high use of water. I was careful to adopt learning from my previous mistakes while setting up the Technical Design departments. As an example: from my personal experience working with suppliers from the northern part of India (20 plus years ago), each operator made an entire garment. This was inefficient both for sample making and bulk production. I knew that alone I can’t change the way of working and that setting up anything is a team effort. Working with the Bangladesh suppliers I learned that the industry was built after the city was built so the factories are in congested locations which is also why the sample rooms were congested. I learned that one has to be flexible and be mindful of the limitations of the suppliers.

What were some of the challenges you faced when developing a supply chain in these areas?

In my experience working with some suppliers at the time was that they did not have knowledge of garments and how they are manufactured i.e., how to sew or create patterns. The understanding was so limited that the workers thought it was good enough to have the size mentioned on the garment, but it didn’t need to match the size of the hangtag.

I learned to be patient thru these challenges and educated the technical teams. It took me and my team a couple of months to build a training manual which included how to lay a garment to measure, what is each point of measure (POM), why we measure, how we measure, why, and how we fit, how to read/understand a Tech pack (TP).

African suppliers can make several classifications including tops and bottoms, swim and, intimate apparel across men, women, and kids.

Africa is mixed in terms of development. Some places in Africa were very modern and others where there was no infrastructure—no airport, no rail, no road and no factory. At one city I had to walk on the tarmac to board my flight. My luggage came in an open lorry. I saw cattle being traded from a distance. And in contrast, I visited a zero-liquid discharge (ZLD) facility for the 1st time in Africa which was very educational. Simply said it’s fascinating!

What are some of the benefits of working with these makers?

It’s duty-free, there is a shorter lead time, and, most importantly, I am proud to be part of building technical design in an environmentally responsible country.

What are some things they are doing to be “environmentally responsible”?

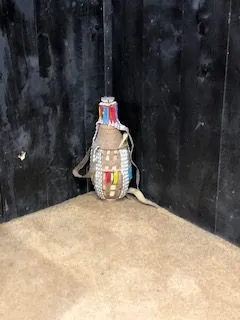

They have a Clean Water Initiative, plastic bags are banned, there are different projects planned for recycling plastic products and making the environment green as an example. Using plastic bottles for building homes, decorating, making crochet…

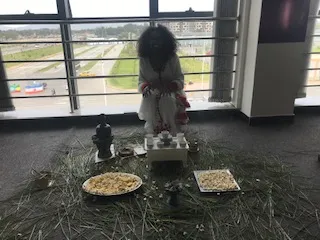

I loved the coffee ceremony they have. They greet guests and make them sit in the special chair. They serve popcorn while women in tribal outfits make coffee in front of you. The coffee needs to be of a certain consistency and strength and is a skill they learn from their mothers. The tradition is that one drinks 3 cups of expresso. While drinking they share stories/experiences.

"Africa is a beautiful continent and in the most natural state, least touched by mankind. The air is clean, the grass is green, and the wildlife is preserved. Alka

Any further words of wisdom to share?

"Be agile, be flexible. Don’t let something you don’t have control overcome in the way of what you have control over.

Alka’s photo journal

Thank you Alka for sharing your many words of wisdom and your incredible journey!

Comments